The company KOMPOZITUM has been providing unique technological services to world producers of carbon strips up to the length of 1350 mm since 2011, especially for the following companies:

Infiltrations

- PanTrac GmbH Berlin

- Morgan Advanced Materials plc Swansea

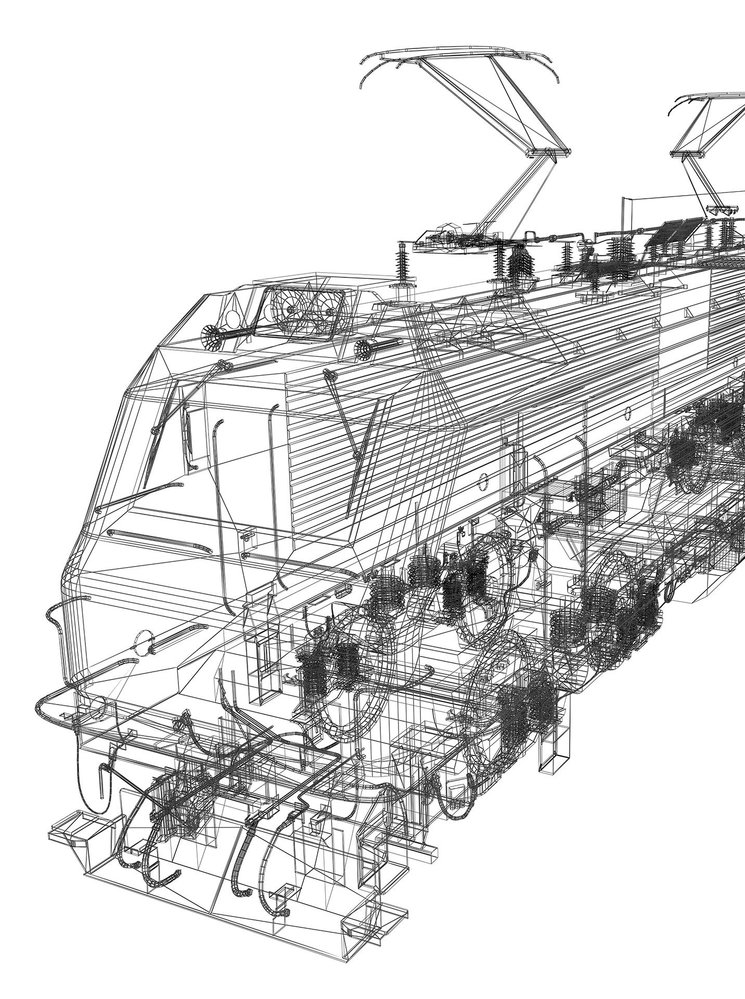

Carbon strips are designed for pantograph systems of electric traction vehicles, such as high-speed locomotives, city trams and trolleybuses in Europe and China.

We infiltrate carbon materials with metals and alloys to the copper melting temperature. By infiltration of carbon strips, we increase properties of basic carbon material in traction systems application:

- higher resistance when operated in areas with high moisture content and icing on overhead lines

- suitable for high continuous current loads up to 15 A/mm of strip width (depending on metal content)

- high strength of the carbon strip, resistance to mechanical damage in operation

- suitable for high speeds up to 350 km/hour

- suitable for optimum connection of a carbon strip with aluminum beam

- suitable for automatic start system (ADD)

- excellent parallel cooperation of a carbon strip versus the overhead line

- reduced impact on radio-communication equipment

- reduced amount of electric arcs on the contact surface of the strip and overhead line

- reduction of maintenance and need to replace carbon strips in operation

Infiltration of carbon materials for pantograph systems of electric traction vehicles is carried out with the following liquid metals:

- pure electrolytic copper 99.9% (mainly for pantograph strips)

- copper alloys with tin - bronze alloys (mainly for pantograph strips)