material: graphite

(isostatically and hydraulically pressed)

Characteristics: fine-grain and medium-grain structure

material: graphite

(isostatically and hydraulically pressed)

Characteristics: fine-grain and medium-grain structure

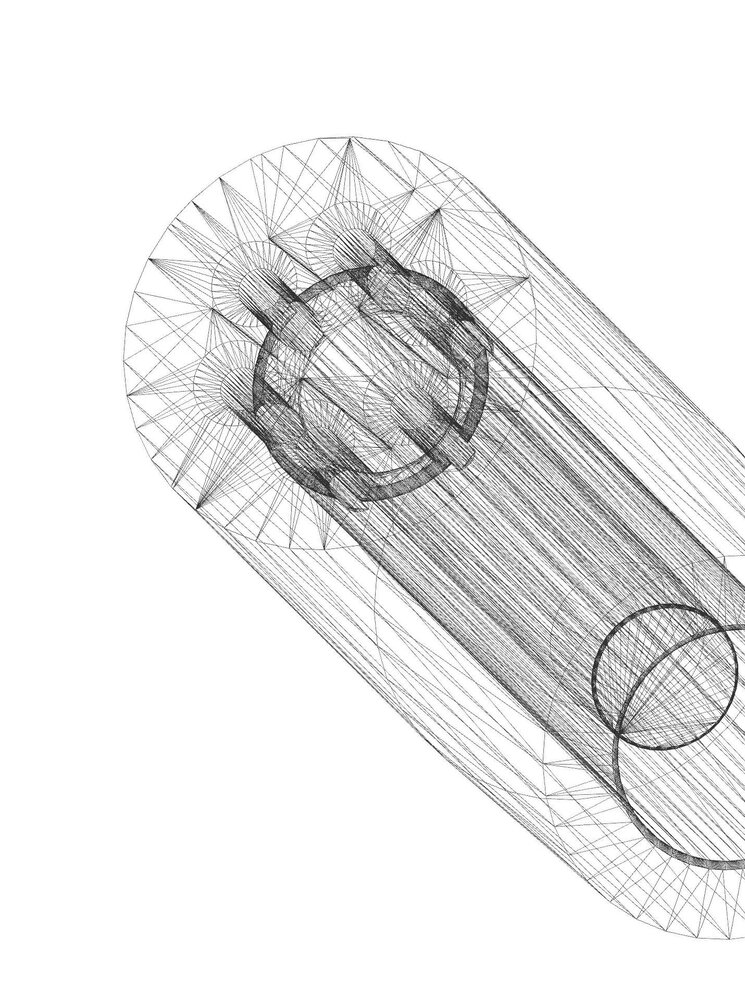

Continuous casting by using graphite molds and formers allows to obtain products of various shapes and profiles from molten metal. Each process has specific requirements on graphite material, such as low friction coefficient for wear resistance, required density or porosity, and others. We recommend our customers optimum graphite material based on our extensive experience.