Heating elements for vacuum furnaces:

Graphite heating elements have optimum electrical resistance, form stability, resistance to high temperatures and thermal shocks.

Graphite heating elements have optimum electrical resistance, form stability, resistance to high temperatures and thermal shocks.

Casting by using graphite molds and mandrels allows to obtain products of various shapes and profiles from molten material. Choosing of a suitable graphite material affects a size and shape of the castings, as well as speed and composition of the cast alloy.

Graphite pads and platters made of graphite materials provide higher efficiency of tools coating process. Unique properties of graphite material in this application include their resistance to high temperatures and form stability.

Graphite scrapers do not damage hot glass on contact and are characterized by high heat shock resistance. Flexibility and dimensional stability of the material guarantee wear resistance in applications.

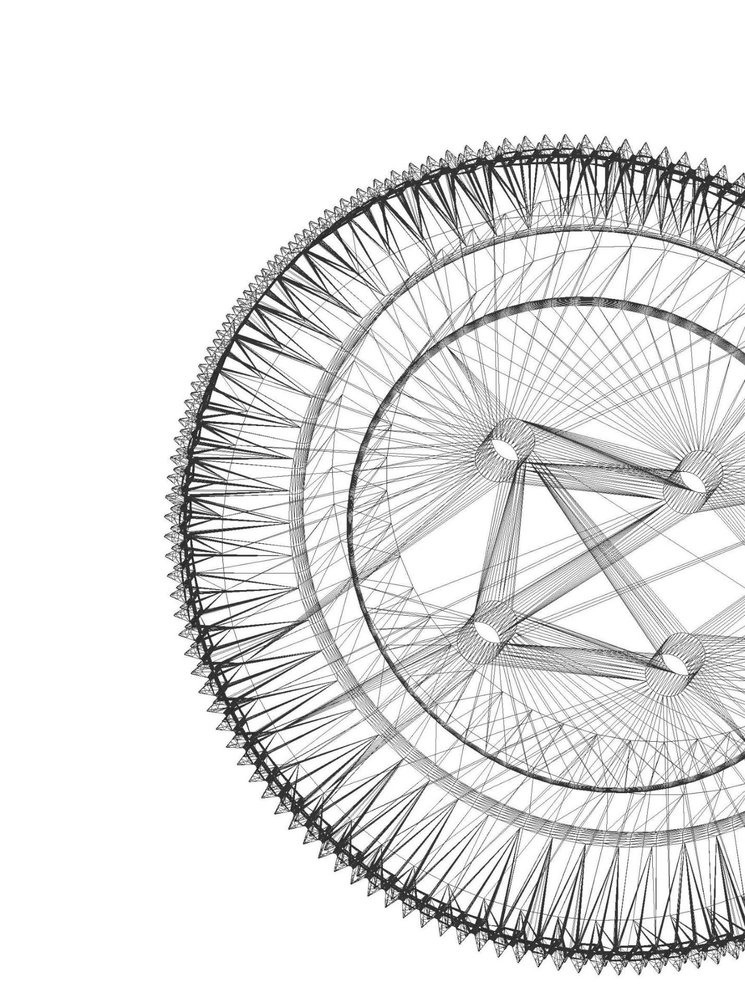

Graphite rotors are characterized by high thermal shock resistance. Antioxidant salt infiltration reduces material oxidation in aluminum alloy degassing applications.

Graphite products for semiconductor technics require higher purity of graphite material than in case of other applications. This technology is based on silicon crystals that are obtained by melting and drawing of silicon metal. These processes take place at very high temperatures and in very extremely corrosive environment.

Long or short fiber graphite insulation is used as effective insulation in cylindrical or quadratic heating vacuum chambers. In addition to soft and hard graphite insulation, we also use graphite foils and CFC plates to protect solid insulations against mechanical damage.

Raft pads used in sintering processes are characterized by higher electrical resistance, lower thermal conductivity and at the same time high strength and hardness of graphite material.

Graphite scorifiers and molds used for melting, casting and chemical analysis of non-ferrous metals are characterized by lower porosity and homogeneous structure of graphite material. The graphite material does not contaminate processed material. It maintains its properties even at high temperatures by using vacuum or protective atmosphere.